-

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

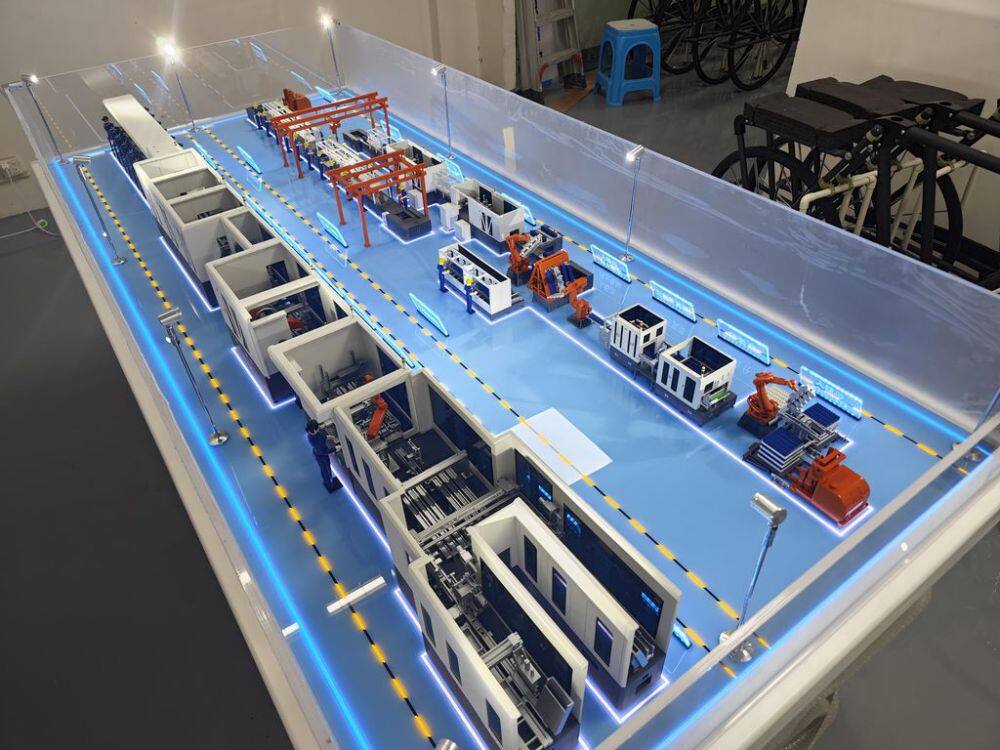

Industrial production line sand table model making factory

2025-09-08 15:57:53

1、 Project Background and Objectives

This plan restores the intelligent manufacturing production line of lithium batteries at a ratio of 1:50, covering three core sections: electrode preparation, cell assembly, and chemical capacity division. By utilizing mechanical linkage and digital twin technology, a dynamic restoration rate of over 90% can be achieved, meeting the dual needs of teaching demonstrations and customer visits.

2、 Core production process flow

1. Construction of production line skeleton

Base system: A modular framework is constructed using aviation aluminum profiles, with reserved equipment installation slots

Conveyor belt system: Micro motor driven polyurethane synchronous belt, with laser engraved anti slip patterns on the surface

Workstation division: Acrylic partitions combined with magnetic signage to achieve flexible production line layout adjustment

2. Production of key equipment

(1) Electrode coating machine

Brass etching mesh roller combined with silicone scraper, reducing the coating process of slurry

Transparent observation window design, built-in LED simulation oven heating effect

(2) Stacking workstation

Stepper motor drives the robotic arm to achieve precise stacking of 0.2mm thick pole pieces

The vacuum suction cup is made of medical grade silicone to ensure smooth operation

(3) Injection sealing system

Micro peristaltic pump connected to glass storage tank for dynamic electrolyte injection demonstration

Magnetron switch triggers automatic sealing cover pressing action

3. Intelligent control system

PLC central control panel: integrated touch screen and status indicator lights, supporting process parameter adjustment

RFID traceability system: Implant chips into each battery cell model to simulate the quality traceability process

AR interaction module: Scan the device's QR code to retrieve a 3D explosion diagram

3、 Artistic processing and detail enhancement

1. Industrial aesthetic design

The main color scheme is a combination of Tiffany Blue (Pantone 15-5519 TPX) and Mechanical Grey (RAL 7035)

Safety warning signs are printed using fluorescent orange (Pantone 158 C) screen printing

2. Environmental creation

Epoxy resin poured anti-static floor, with metal powder sprayed on the surface to simulate a conductive layer

Polyurethane foam is used to make ventilation ducts, with embedded optical fibers to simulate airflow guidance

4、 Quality Control Standards

Dynamic accuracy

Repetitive positioning error of robotic arm ≤ 0.3mm

Belt speed fluctuation rate<5%

Visual restoration

The equipment trademark adopts macro UV printing, with a font height of not less than 1.2mm

The cable is woven with silicone sleeve, and the diameter error is controlled within 0.05mm

Tags: industrial models, sand table models, model