-

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

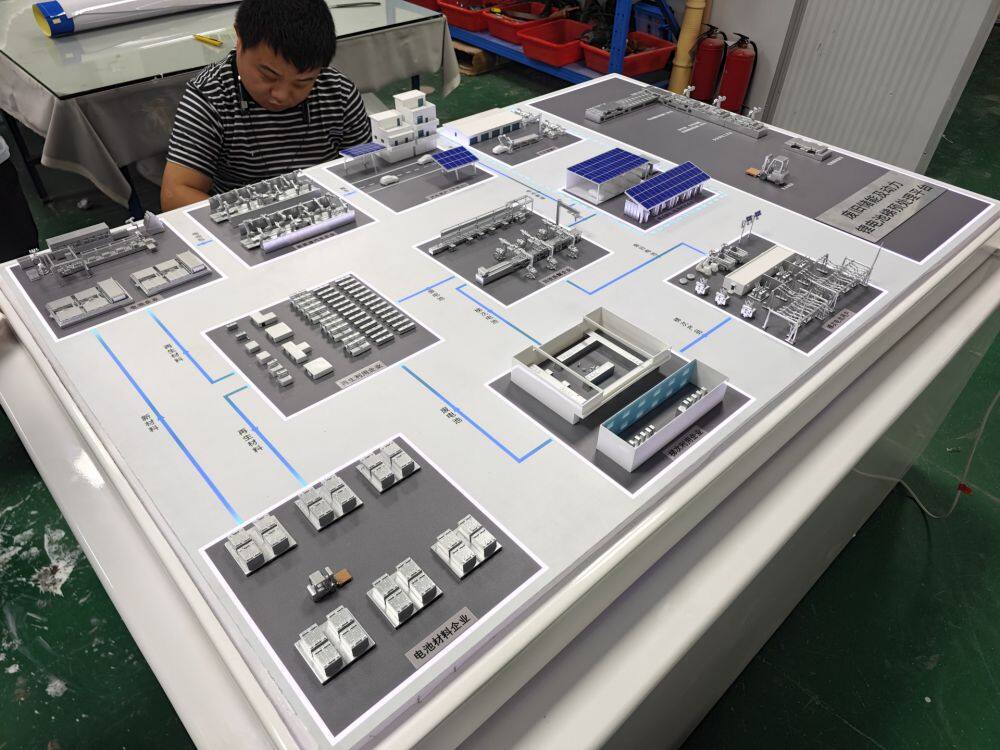

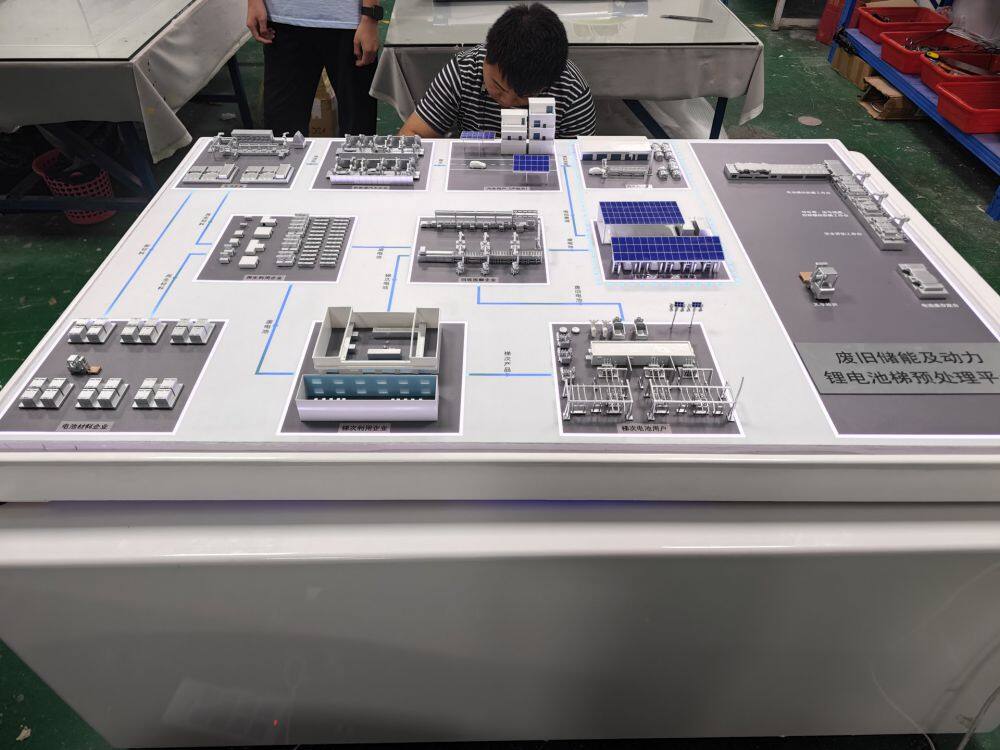

Sand table model making factory for waste battery disposal

2025-09-08 16:02:19

1、 Project positioning and design philosophy

This plan restores the modern waste battery crushing and sorting production line at a scale of 1:50, showcasing the three core sections of pretreatment, crushing and separation, and metal recovery through modular design, and simulating the closed-loop process from battery recycling to resource regeneration with a dynamic demonstration system. The design emphasizes a visual balance between "technological sense" and "environmental friendliness", with a target of 90% restoration.

2、 Core manufacturing process

1. Construction of production line structure

Main framework: A three-dimensional skeleton is constructed using 304 stainless steel profiles to ensure load-bearing stability; Each section is isolated with 5mm acrylic board, and the texture of the laser engraved observation window is used

Equipment simulation:

Crusher: 3D printed ABS material shell, internal installation of micro motor driven movable blade

Sorting device: The magnetic separation module is embedded with neodymium magnets, and the eddy current sorting area uses aluminum foil to simulate the metal separation effect

Electrolytic cell: transparent resin pouring, built-in LED gradient light simulating electrolyte reaction

2. Dynamic system design

Conveyor belt system: N-scale model track modification, equipped with photoelectric sensors to control the intermittent movement of battery modules (3D printed PLA material)

Dust collection demonstration: Install atomization device at the top of the crushing section, and simulate negative pressure dust removal with blue LED light effect

Data dashboard linkage: Mini OLED screen displays real-time simulated processing volume, metal recovery rate and other key indicators

3、 Artistic processing and detail enhancement

1. Color scheme

Industrial equipment: The main color scheme adopts RAL 7035 (light gray) with safety yellow warning tape

Hazardous waste identification: UV printed corrosive substance label, accurately reproducing the GB 18597 standard style

Background wall: Spray painted gradient green abstract pattern, symbolizing the concept of resource recycling

2. Special effects processing

Crushing section aging: Mixing iron oxide powder with matte agent to simulate metal wear

Electrolyte simulation: Epoxy resin mixed with fluorescent dye, exhibiting ion movement effect under UV lamp irradiation

Personnel flow: 1:50 scale 3D printed dolls are used, and differentiated PPE equipment is configured for different workstations

4、 Implementation of interactive functions

Multi mode demonstration:

Automatic mode: PLC controls continuous operation throughout the entire process

Step by step mode: Select a specific section for detailed explanation through the touch screen

AR augmented reality: Scan the device QR code to view the 3D disassembly animation

Security warning demonstration: red strobe light combined with buzzer simulates overheating alarm

Tags: industrial models, sand table models, model