-

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Aerospace model manufacturer

2025-09-09 15:29:45

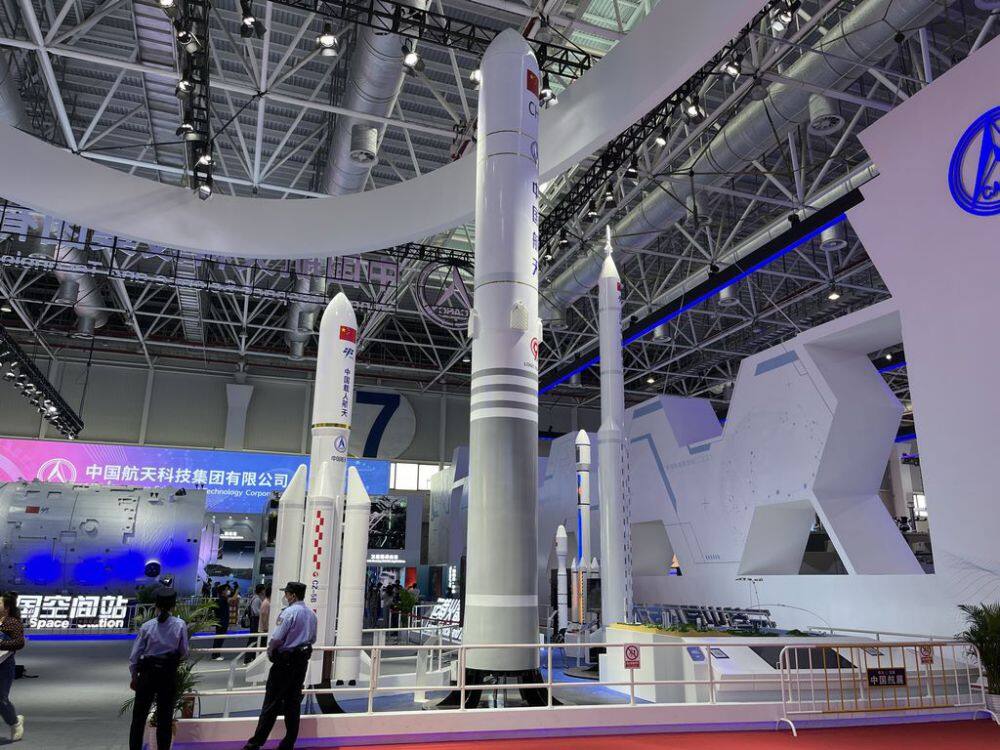

Case Study of Aerospace Rocket Model Production

The aim of this project is to create a space rocket model with a 90% fidelity, highlighting the structural features, surface details, and iconic coatings of the rocket. The model will highlight the realistic reproduction of arrow proportions, engine details, and surface textures, focusing on craftsmanship and visual representation.

1、 Design and Material Selection

The model is designed proportionally, and the main body uses lightweight ABS plastic pipes as the main structure of the arrow body, balancing strength and processing convenience. Complex curved components such as fairings and engine nozzles are achieved using high-precision 3D printing (photosensitive resin) to ensure accurate appearance. Internally reinforced with aluminum alloy brackets to enhance load-bearing capacity and avoid deformation.

2、 Arrow body production and detail processing

Segmented production of rocket body: Each level of rocket is cut and polished with ABS pipes, and then docked. The joints are filled with soil and polished smooth. The surface reinforcement ribs and pipeline details are cut and bonded with polyester adhesive sheets, while small components such as cabin doors and sensors are made with etched sheets (made of brass material) and precisely pasted with tweezers.

Engine group production: The main engine nozzle is made by turning aluminum alloy parts, and the interior is sprayed with matte black to show depth. The attitude engine is made of copper tube microfabrication, with aluminum alloy clamps added to the connection between the booster and the main body, and micro resin buckles used for bolt heads.

3、 Pre coating treatment

Spray 1200 mesh gray soil on the entire model, inspect and repair any defects. Spray matte white primer on the white part of the arrow body, and spray metal primer after covering the metal area. Use a cutting needle to deepen the panel segmentation line, and carve grooves on the edge of the cabin door to ensure clear color separation in the later stage.

4、 Color separation coating and identification treatment

The main coating adopts segmented cover spraying: the white arrow body is coated with water-based matte paint, and the matte dark gray area of the fuel tank is precisely delineated by pre cut cover paper. The engine nozzle is sprayed with high-temperature resistant metal color (aluminum color+blue purple gradient), and locally dry swept copper color shows a burning effect.

Identification and Text Processing: Customized printing of water stickers, including national flags, warning text, manufacturer logos, etc. Soak in a softener before attaching, flatten with a cotton swab to remove bubbles after bonding, and finally spray a semi gloss protective paint to achieve a uniform gloss.

5、 Aging and texture expression

Emphasize the details of the concave lines with stain solution (dark brown), and use a cotton swab dipped in solvent to wipe the raised areas to form natural shadows. Apply brown powder paint to the engine area to simulate fuel residue, and lightly scratch the arrow body with a pencil to show a sense of metal wear. Spray a slight gradient color on the top of the fairing to simulate atmospheric friction effect.

6、 Final assembly and base configuration

Each level of rocket is connected by an internal magnetic attraction structure, making it easy to disassemble and display. The model is fixed on a customized base (carved from black walnut wood), with task badges etched on the surface of the base. The bracket is a stainless steel polished rod, forming a texture contrast with the arrow body.

7、 Characteristics of Achievements

This model achieves high-precision restoration by combining material combinations (ABS, resin, metal) with manual craftsmanship. Emphasis is placed on the clarity of color separation boundaries, accuracy of identification, and moderate aging, avoiding overly exaggerated aging effects. The overall visual effect is rigorous and layered, meeting the requirement of 90% restoration.

Tags: sand table models, industrial models, Aerospace model