-

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

yoyo

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Aircraft engine model manufacturer

2025-09-10 15:02:47

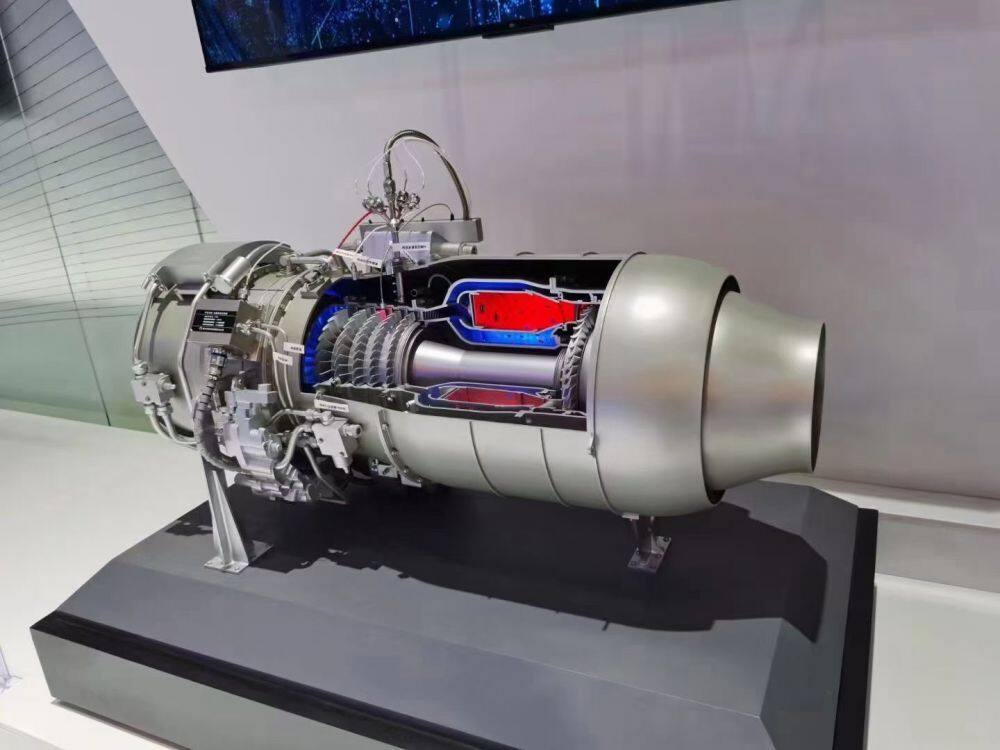

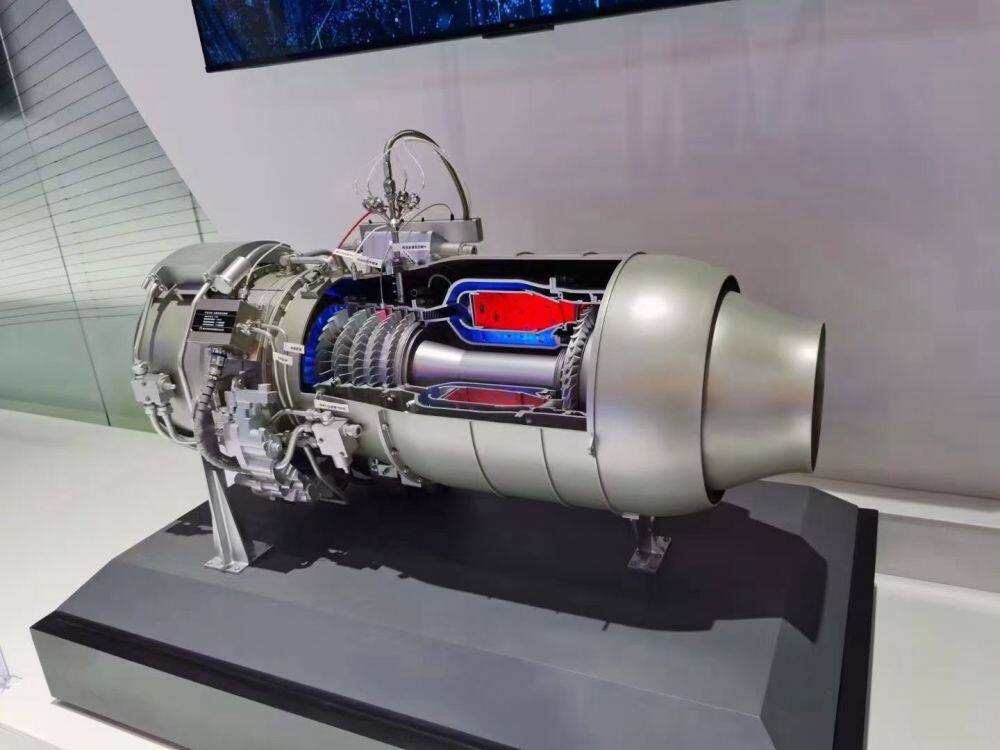

Scheme for making cross-sectional model of turbofan engine

1、 Model display characteristics and design concept

This plan focuses on the cross-sectional model of turbofan engines and highlights the following core structural features:

Airflow channel system: Clearly present the complete airflow path from intake to exhaust

Compressor structure: display the arrangement and angle of multi-stage compressor blades

Combustion chamber layout: distribution structure of annular combustion chamber and fuel injector

Turbine system: blade array of high-pressure turbine and low-pressure turbine

Sectional design: Adopting a 30 ° oblique section scheme, showcasing the compressor, combustion chamber, and turbine simultaneously

The design concept of the model is to achieve a 90% structural restoration degree through precise cutting angles and material selection, while also considering the safety and display effect of international transportation.

2、 Material selection and characteristics

Main structural materials

Sectional shell: 6mm thick acrylic sheet (transparent/semi transparent), using hot pressing molding process

Metal components: aluminum alloy (compressor/turbine disc), stainless steel (shaft system)

Blade material: carbon fiber or aviation aluminum, ensuring lightweight and strength

Dynamic component: N20 deceleration motor (6RPM) drives fan rotation

Special functional materials

Transparent resin (displaying internal pipeline structure)

LED strip (simulating the brightness of the combustion zone)

Magnetic connectors (convenient for modular disassembly and assembly)

3、 Core manufacturing process

Precision component manufacturing process

Compressor production:

Five axis linkage machining center for producing axial flow blades

The centrifugal part adopts CNC precision machining

Surface anti glare treatment

Combustion chamber fabrication:

3D printing flame tube structure

Transparent section displays the layout of internal fuel injectors

Aging treatment simulates high-temperature usage traces

Turbine system:

Single crystal high-temperature alloy blade (simplified version)

The shaft system is made of 304 stainless steel

Weight balancing treatment

Assembly process flow

Install shaft system and internal components

Assemble compressor and turbine blades

Install combustion chamber and power output shaft

Finally, install the sectional shell

4、 Post processing and coloring techniques

Surface treatment technology

Metallic texture: sprayed with metallic paint (primer color paint protective paint three-layer process)

Identification production: water sticker process with equipment nameplate added

Aging treatment: lightly polished edges to simulate usage marks

Color scheme design

Compressor area: Silver gray

Combustion chamber area: orange red gradient

Turbine area: High temperature alloy gold color

Shell: Transparent Acrylic Original Color

5、 International Transportation Packaging Solutions

Protective packaging design

Modular packaging: decomposed into 3 independent modules (front/core/rear)

Cushion material: EVA foam customized lining+bubble film filling

Moisture proof treatment: built-in silicone desiccant and humidity indicator card

Transportation protection measures

Metal parts: PE film seal after applying rust proof oil

Electronic components: packaged in anti-static bags, separately fixed

Transparent component: pearl cotton wrapped to prevent scratching

Tags: industrial models, engine models, equipment model